Feature

Feature National Plastic Pallets are positively outstanding.

The pallet system produced by advanced technology of National Plastic cp., Ltd. which had acquired Korean Industrial Standard mark for the first time among Korean industries, has durability and efficiency. These advantages make our pallet system helpful for saving costs and scientific transportation control.

As the first KS Mark (Korea Industrial Standard) acquired industrial plastic pallets manufacturing company of Korea, the products of National Plastic Co., LTD are advantageous for its customers by helping reducing cost and expenses as well as operating systemized logistics management with its highly advanced technology.

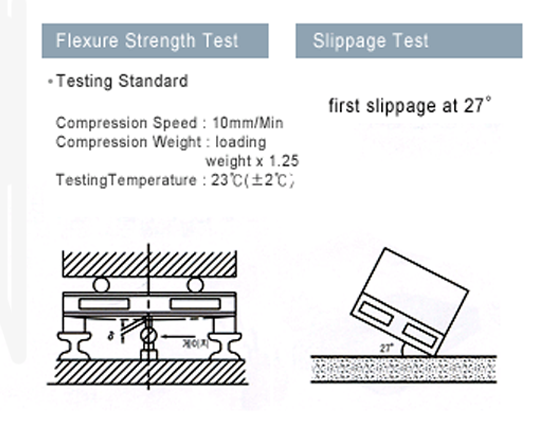

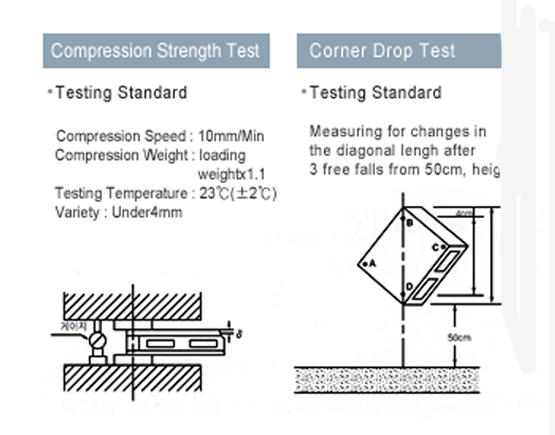

Pallet Quality Test (Protocol based on KIS)

National Plastics persist on the best quality

The shape of our pallet may be imitated no one can our quality.

Drivers choices are available depending on the usage and the standard such as flooring, plain, handcart, GMP ,and automated warehouse-types of pallets. They are developed to withstand from lightweight to medium-weight load so that you can select according to the delivery system specificity of your company.

Made with high-density polyethylene(H/D PE), molded by foaming makes it durable against high impact or pressure. Since they are cold and heat resistant products that can withstand extreme temperatures from as low as -50aºC as high as 60ºC, usage in cold storage is possible for they are not affected by seasonal changes.

The supporting system between the frames is placed for safety of stacked goods and to strengthen the frame work. This systemic pallet is suitable for the automated area, with dynamic factor increased in its design to minimize flexure ratio in automated rack facilities.

It increases work efficiency in a small space since it s designed to work in 4 different directions when using the forklift truck.

Compared to wood and iron, the light-weighted material makes if work-efficient. Since it does not absorb moisture it is suitable for storing and transporting items such as paper products or cement.

Special method used for adhesion of connecting parts(without protruding metal fasteners such as bolt and nut, and nails)prevents accident from occurring for the workers as well as being safe for the stacked items.

The life od the pallets are semi-permanent and since they do not require repairs like the wooden pallets,the national pallets will not only reduce the expenses but also will bring more profit to the users.

The problems of decomposing woods or damages done by protruding nails have been solved to keep the packaging clean and free from and damage.

Compared to other companies,the rubber packing is inserted far down,making it safer for moving and transportaion for one does not have to worry about missing rubber packing.

Scientifically designed National Plastic Pallet-

Check out the differences.

The life od the pallets are semi-permanent and since they do not require repairs like the wooden pallets,the national pallets will not only reduce the expenses but also will bring more profit to the users.

Without any connected parts,the design is durable and economical since it won't break when being transported by the forklift trucks.

The upper grill surface is finished with embossing to prevent slippage during stacking,which makes it safe and convenient for work and transportation

Exclusive vertical connecting molding,compared to horizontal molding,prevents breaking while being transported by forklift trucks and has superior durability.